What we do

"The right skill at the right time and right location"

- Home

- Our services

Our services

What we do

OUR RANGE OF EXPERT SERVICES

OGMI provides professional teams quickly. Our specialists have strong knowledge to ensure the completion of your projects with respect to quality, schedule and budget, around a world. Our highly technical, dedicated, and experienced professionals perform in various areas as follow:

Engineering services

O&G Materials Inspection, we have extensive engineering background, knowledge, expertise, and experience to successfully execute projects of most sizes with variety level of complexity and scheduling. Our expertise and capabilities include professing and resolving engineering challenges that are associated with a variety of project type, project scale, budget size, geographical location, and climatic conditions. We are highly professional and diligent engineers deliver quality and innovative services to the oil and gas industry. Our expertise extends throughout the regulations, requirements and processes of the oil & gas industry. Our expertise and capability span exploration and production. More importantly, we have the knowledge, expertise and experience working with all aspects of industry regulation-required environmental and social compliance requirements and remediation programs.

Skilled workforce outsourcing

O&G Materials Inspection was created by oil and gas professionals, who know what companies are looking for in terms of personnel and we are dedicated to provide skilled and experimented personnel for each task our customer needs to carry out.

Skilled workforce outsourcing

O&G Materials Inspection was created by oil and gas professionals, who know what companies are looking for in terms of personnel and we are dedicated to provide skilled and experimented personnel for each task our customer needs to carry out.

Technical assistance service

O&G Materials Inspection has specialist head hunting and general recruitment teams to identify and assess Project Services professionals for our Upstream & Downstream clients.

We target Engineers, Quality Assurance and Quality Control Engineers, Health Safety Security & Environment Engineers, Inspection Engineers, Document Controllers and Surveyors.

Active corrosion protection Application inspection, as:

- Cathodic Protection Philosphy

- Corrosion engineering Study

- Anodes Manufacturing

- Anodes installations process (welding and /or Pin Brazing process)

- Cathodic protection survey

In case of needed, we also offer both destructive and non-destructive Inspection Services, QA/QC Oil Field Services Companies, Welding Inspection etc. Our experimented staff operates during the fabrication, the assembly and/or the repairs of your equipment and structures. These interventions may happen in your workshops, on your construction sites, within manufacturing or assembly units. We assure the experience of our inspectors in equipment manufacturing according to diverse codes: ISO, ASTM, NACE, ASME, EN, AWS, API, DNV standards for instance.

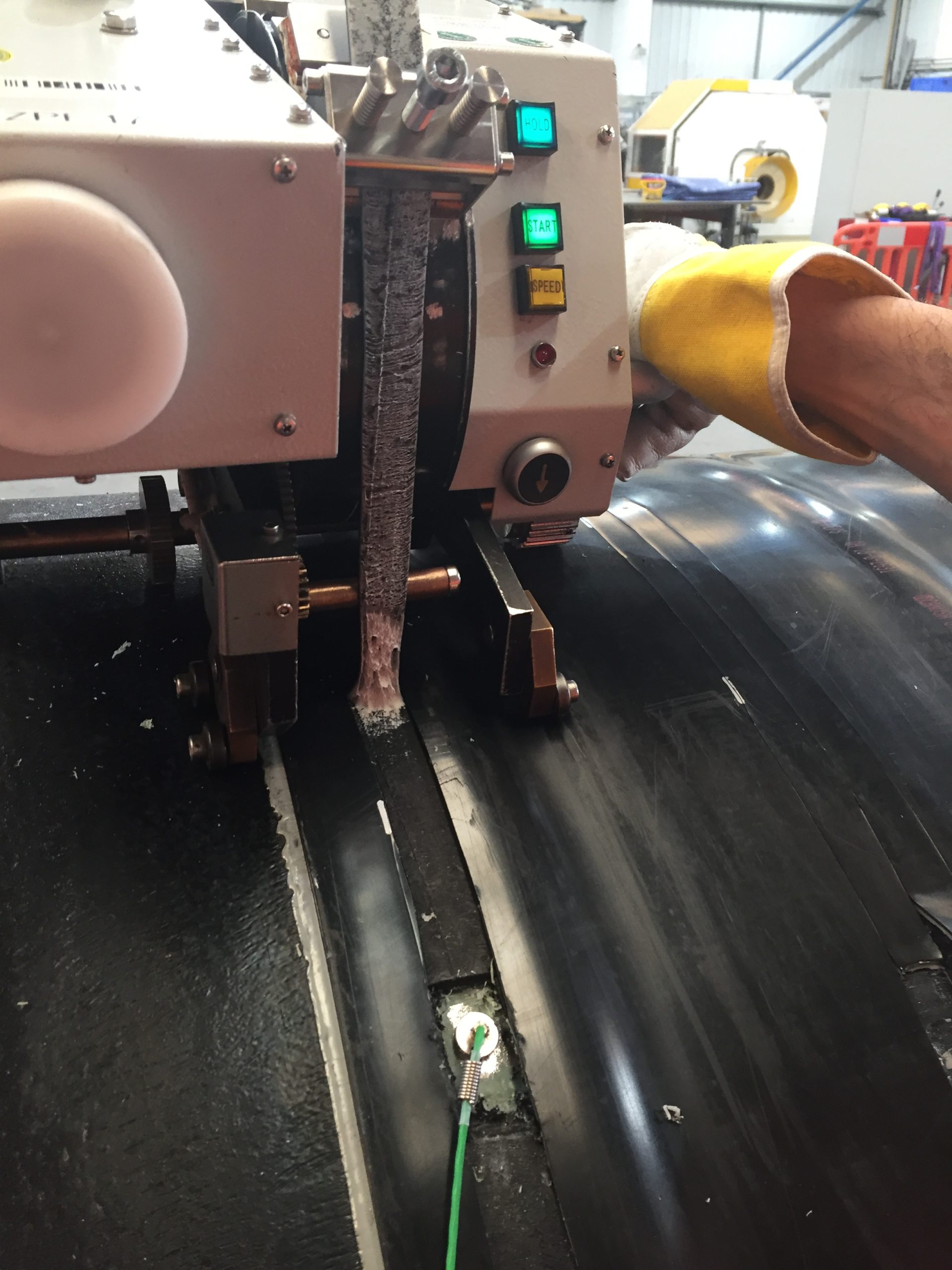

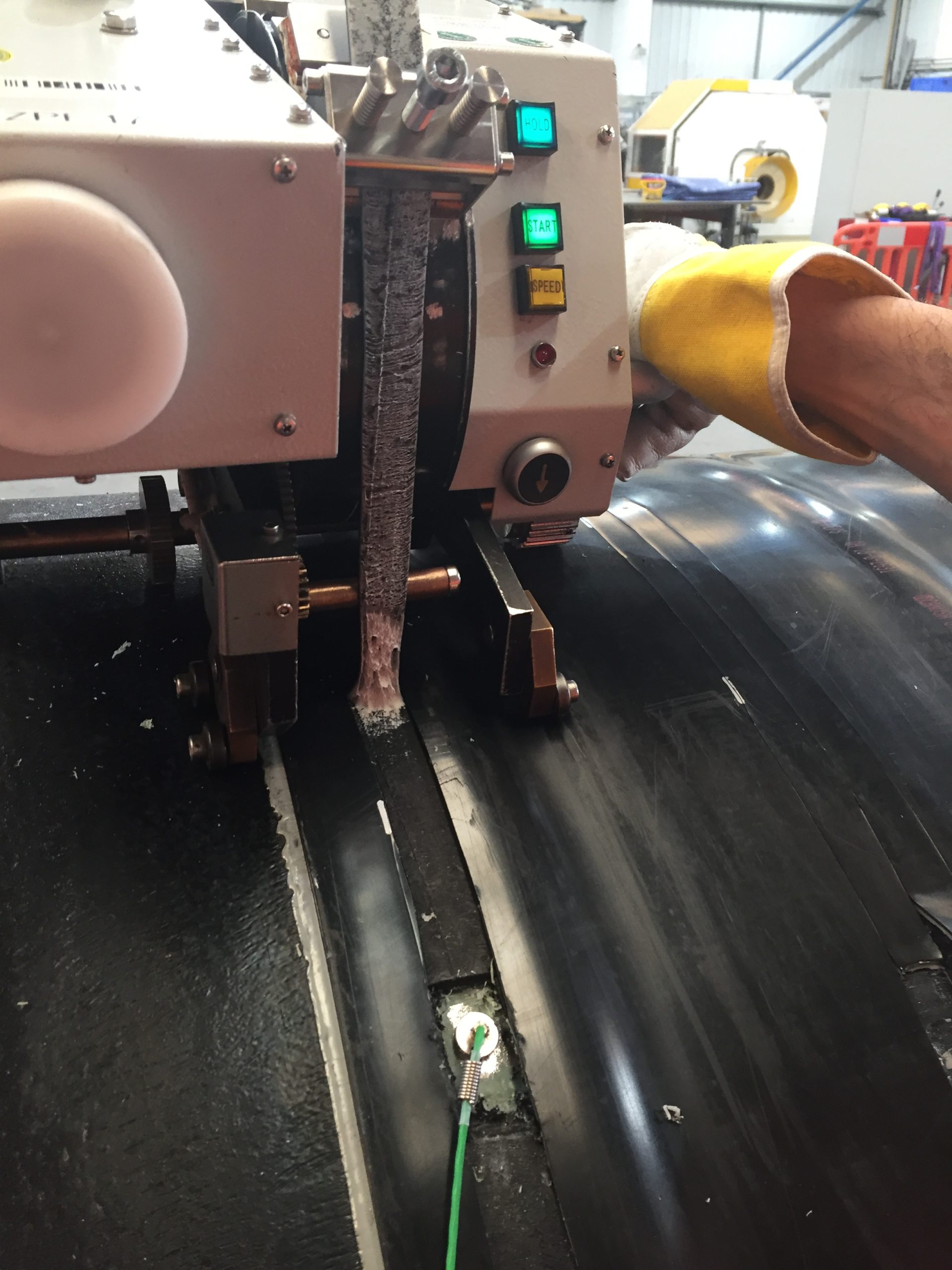

Coating and corrosion inspection services

O&G Materials Inspection offers a pipelines corrosion protections service, as for:

Passive corrosion protection application inspection, either for the application of Parent coating and or for Field Joint Coating pipes end application. as:

- Anticorrosion coating

- Insulation coating

- Painting coating application

Furthermore, in accordance with national and international regulations, they also keep track of in-service equipment. Depending on contractual and technical requirements, our personnel are willing to follow-up the manufacturing at suppliers’ site for temporary mission or continuous and uninterrupted mission. Our specialists make themselves available for interventions accordingly to your needs and expectations. O&G Materials Inspection, we take care of our employees’ well-being as much as the compliance with local and international regulations.

Coating and corrosion inspection services

O&G Materials Inspection offers a pipelines corrosion protections service, as for:

Passive corrosion protection application inspection, either for the application of Parent coating and or for Field Joint Coating pipes end application. as:

- Anticorrosion coating

- Insulation coating

- Painting coating application

Furthermore, in accordance with national and international regulations, they also keep track of in-service equipment. Depending on contractual and technical requirements, our personnel are willing to follow-up the manufacturing at suppliers’ site for temporary mission or continuous and uninterrupted mission. Our specialists make themselves available for interventions accordingly to your needs and expectations. O&G Materials Inspection, we take care of our employees’ well-being as much as the compliance with local and international regulations.

Active corrosion protection Application inspection, as:

- Cathodic Protection Philosphy

- Corrosion engineering Study

- Anodes Manufacturing

- Anodes installations process (welding and /or Pin Brazing process)

- Cathodic protection survey

In case of needed, we also offer both destructive and non-destructive Inspection Services, QA/QC Oil Field Services Companies, Welding Inspection etc. Our experimented staff operates during the fabrication, the assembly and/or the repairs of your equipment and structures. These interventions may happen in your workshops, on your construction sites, within manufacturing or assembly units. We assure the experience of our inspectors in equipment manufacturing according to diverse codes: ISO, ASTM, NACE, ASME, EN, AWS, API, DNV standards for instance.

Quality skilled training services

We provide high quality training to oil and gas personnel, within our core specialties

Our training is performed by qualified instructors, on our premises or at customer’s sites.